custom rotomolding

Rotational molding is a manufacturing process that relies on gravity and heat to produce parts with exceptional strength. The finished product is a stress-free, lightweight and seamless design that is very durable.

custom rotomolding

Rotational molding is a manufacturing process that relies on gravity and heat to produce parts with exceptional strength. The finished product is a stress-free, lightweight and seamless design that is very durable.

ABOUT CUSTOM ROTOMOLDING

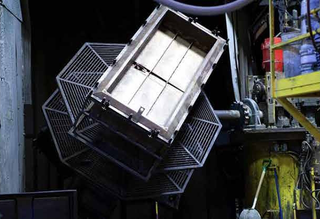

Plastic powder is placed into a heated hollow mold and is rotated in two perpendicular axes as it melts and disperses evenly around the interior surfaces of the mold. The rotation continues during both the heating and cooling phases. Once the plastic is stable, it then enters the cooling cycle. After cooling the rotation is stopped and the finished part is removed from the mold.

Advantages of rotational molding include design flexibility, durability, low cost tooling and uniform wall thickness. A wide range of sizes and shapes can be molded. Rotomolding also has many options for colors, material selection and textures. Very little

material is wasted during the process, and excess material is often re-used, making it economical and environmentally friendly.

Rotomolding tools can be machined, cast or fabricated from materials such as steel, aluminum or stainless steel. Cast and machined molds are best when tight tolerances are needed, or cosmetic finishes are important to the finished product. Cast molds offer a wide range of finishes from wood grain to a mirror finish. Fabricated molds are more economical than cast or machined molds but oer less options for finish.

BUILT IN THE HEARTOF USA.

IRP’s manufacturing and fabrication plants in Decorah, IA are equipped with state-of-the-art Ferry rotomolding machines, CNC router, dedicated foam room and equipment, plasma treater, and full assembly line. We have a wood shop and a full metal-working shop with 50+ years of experience in our expert sta.

Past and current clients include Fortune 500 companies such as Anheuser Busch InBev, MillerCoors, PepsiCo, Gatorade, Coca-Cola, and many more. Our experience in partnering with OEMs and companies from all trades has led us to being recognized as leaders in the industry.IRP’s manufacturing and fabrication plants in Decorah, IA are equipped with state-of-the-art Ferry rotomolding machines, CNC router, dedicated foam room and equipment, plasma treater, and full assembly line. We have a wood shop and a full metal-working shop with 50+ years of experience in our expert sta.

We work alongside clients to develop solutions for converting products from metal, wood, fibreglass and other materials into wholly integrated, rotationally molded plastc designs.